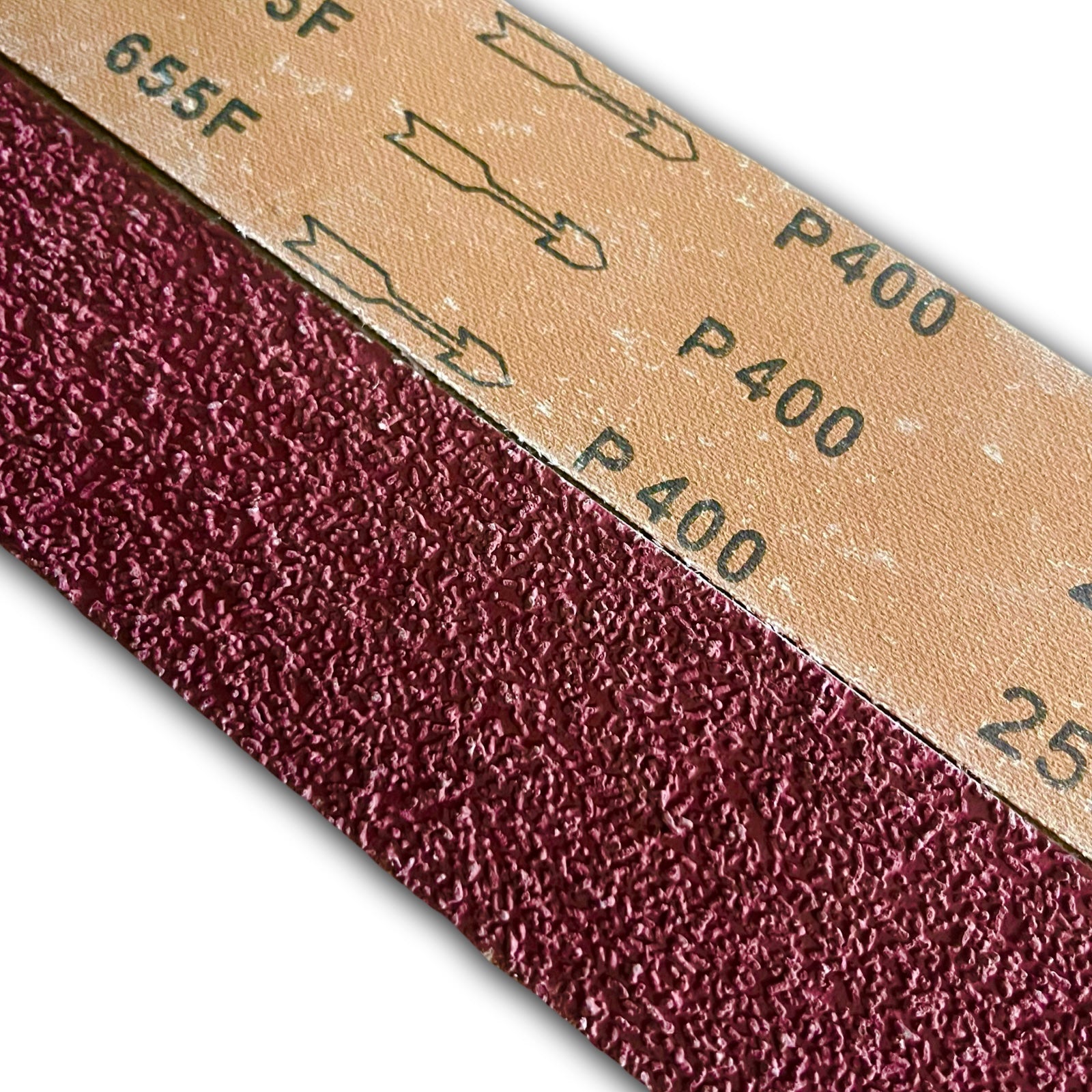

Conglomerate Finishing Belt 120-400 Grit - 2x72" (50x1830mm)

Designed for precision finishing and long-lasting performance, these belts feature a unique conglomerate aluminium oxide grain structure. Instead of traditional single-point grains, conglomerate belts utilise clusters of fused abrasive particles. This engineered structure delivers consistent cutting performance and extended belt life across a wide grit range (120 to 400).

Key Features:

-

Conglomerate Grain Technology:

Multiple abrasive grains are bonded into singular clusters. As the outer grains wear, fresh sharp edges within the cluster are exposed, maintaining cutting efficiency over time.

-

Consistent Surface Finish:

Reduced scratch depth and more uniform abrasion patterns help achieve cleaner, smoother finishes—ideal for preparing surfaces for polishing, satin finishing, or coating.

-

Efficient Stock Removal:

Performs well in medium to high pressure applications. Maintains steady material removal rates without rapid wear or glazing.

-

Longer Belt Life:

The multi-layered grain structure wears more gradually than conventional abrasives, resulting in fewer belt changes and improved cost-efficiency.

-

Versatile Grit Range (120-400):

Suitable for everything from intermediate blending and surface refinement to fine finishing and pre-polish stages

Applications:

-

Knife and tool finishing

-

Blacksmithing and fabrication

-

Metal prep for anodising or coating

-

Wood and composite sanding where consistent finish is critical