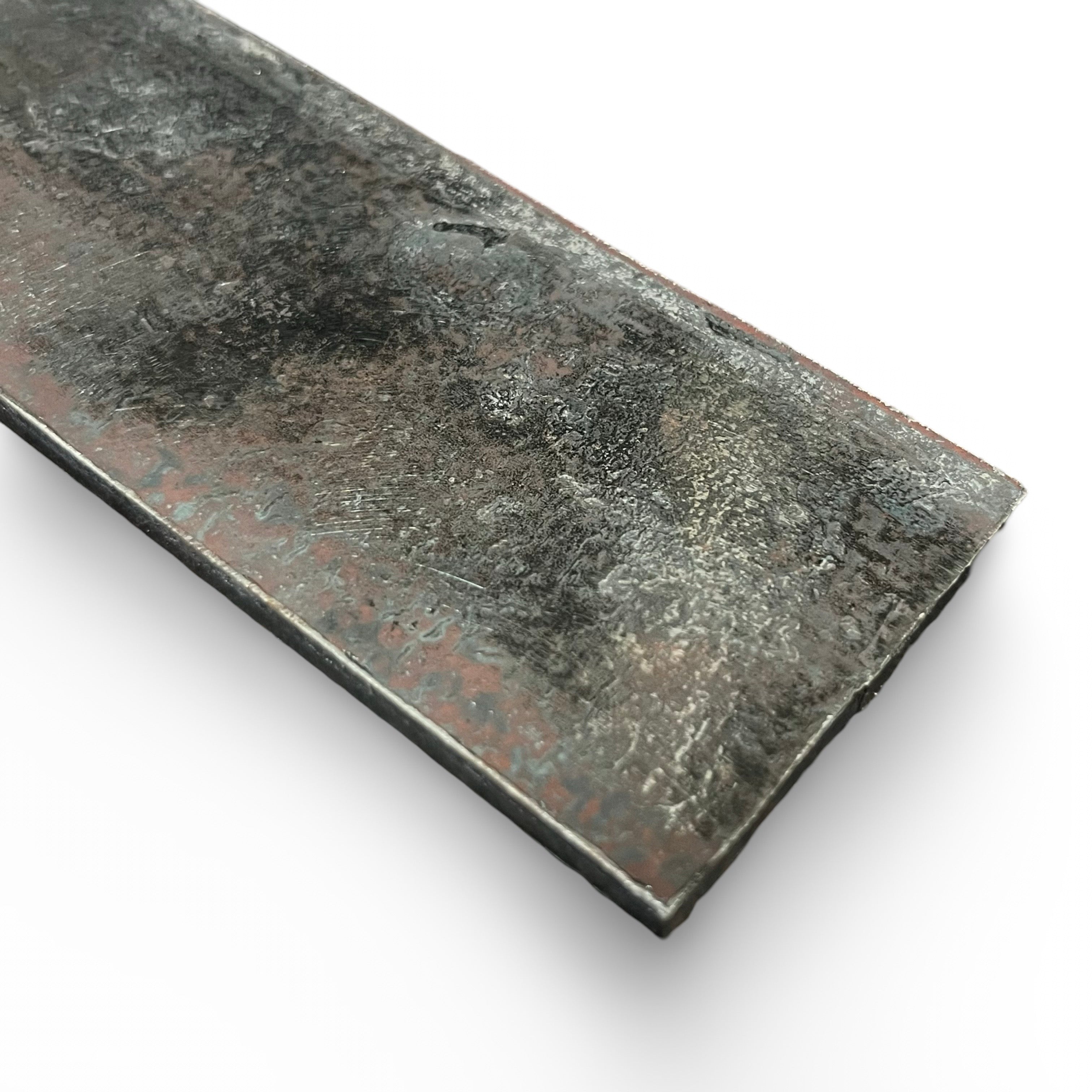

Hitachi Shirogami White 2 Soft Iron Clad San Mai

Shirogami 2, also known as White 2 or Shiro-Ko II, is a high-purity carbon steel produced by Hitachi Metals. Revered in traditional Japanese knife-making, this steel is prized for its exceptional sharpness and ease of sharpening. Its extremely low phosphorus (≤ 0.025%) and sulfur (≤ 0.004%) content ensures a clean and fine grain structure, perfect for creating ultra-fine edges.

Shirogami 2 is slightly less hard and wear-resistant than Aogami steels but excels in achieving extreme sharpness with minimal effort. This makes it an excellent choice for knives that prioritize razor-sharp edges, such as kitchen knives and precise cutting tools.

This steel is supplied hot rolled and annealed, this surface is quite rough and has pitting due to the forged iron. It is soft and easily cut, ground, drilled, and filed. Once polished, etch in hydrochloric and ferric acid to bring out the traditional San Mai contrast between the soft iron cladding and White 2 core.

If you do not micro-texture (hammer while cold or hot) to disrupt the pattern, you will achieve straight, clean layers.

Composition

White Paper 2 Core:

-

Carbon – 1.00-1.10%

-

Manganese – 0.20-0.30%

-

Phosphorus – ≤ 0.025%

-

Sulfur – ≤ 0.004%

Soft Iron Cladding:

- Low-carbon iron provides toughness and ease of forging while protecting the high-carbon core.

Performance Characteristics

Toughness: 7/10 – High toughness due to its soft iron cladding, making it more resistant to chipping and cracking during use.

Edge Retention: 6/10 – Good edge retention, slightly lower than Aogami steels, but excelling in achieving and maintaining razor-sharpness.

Corrosion Resistance: 4/10 – The high-carbon core is prone to rust and patina, requiring regular maintenance. However, the soft iron cladding is less reactive than pure high-carbon steel.

Recommended Heat Treatment

-

Coat Blade: Use an anti-scale compound or seal in double-crimped 321 or 309 grade stainless steel tool wrap.

-

Austenitize: Heat to 780-820°C and hold for 10 minutes.

-

Quench: Use oil or water quenching for maximum hardness and edge sharpness.

-

Temper: Temper at 150-200°C for 2 hours, twice, to achieve the desired hardness and relieve internal stresses.

As-Quenched Hardness (Approximate)

- After quenching from 780-820°C: 62-64HRC

Recommended Working Hardness

60-62HRC – Optimal for achieving a balance between edge retention, sharpness, and toughness.

NOTE

To enhance stability and reduce the risk of delamination between the core and cladding, a stress-relief temper (~100°C for 2+ hours) is recommended after the primary tempering process.