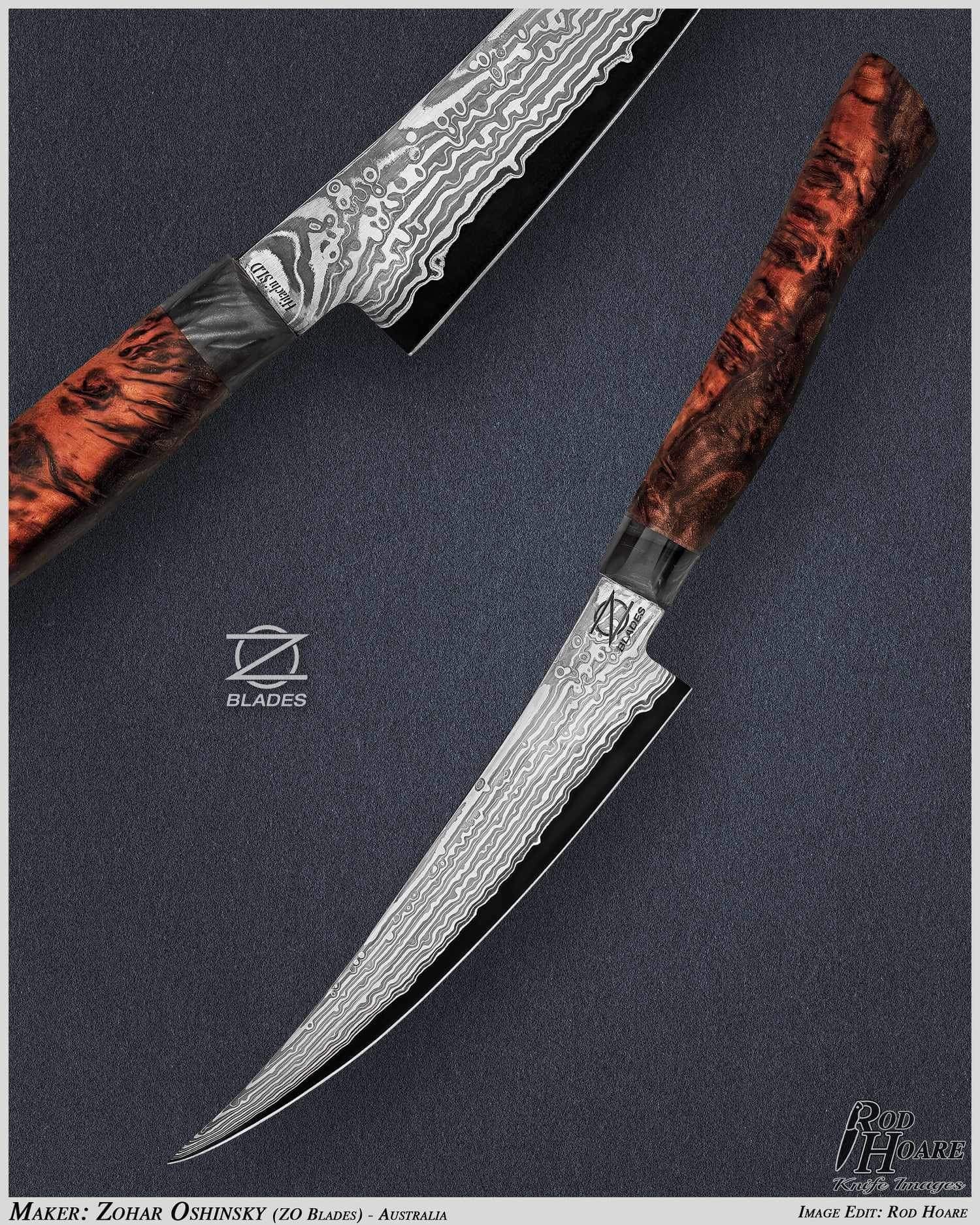

Hitachi SLD Stainless Damascus Clad

Hitachi SLD San Mai with Damascus Stainless Steel Cladding, Made by Sanwa Special Steel company.

This steel is supplied cold rolled and annealed. It has a smooth surface free of decarburisation or pitting and is soft and easily cut, ground, drilled, and filed. Once polished etch in Hydrochloric and ferric acid to bring out the pattern.

If you don't micro texture (Hammer while cold/hot) to disrupt the pattern you will get straight layers.

Hitachi SLD steel is a premium high-speed tool steel that has gained popularity among knifemakers due to its excellent wear resistance, toughness, and edge retention. Similar to D2 tool steel, it is a semi-stainless steel with a high carbon and chromium content, which provides it with good corrosion resistance and excellent edge retention properties. However, unlike D2, it has a higher vanadium content, which improves its wear resistance, making it an ideal choice for high-end kitchen knives and other cutting tools that require superior edge retention and durability. Hitachi SLD steel can be heat treated to a high hardness level and is relatively easy to work with, making it a popular choice among knifemakers looking for a premium steel that offers excellent performance and ease of use.

Steel Composition

Carbon – 1.60%

Chromium – 11.00%

Molybdenum - 0.90%

Vanadium - 0.25%

Nickel - 0.50%

Manganese– 0.60%

Copper - 0.25%

Silicon – 0.10%

Phosphorus - 0.03%

Sulfer - 0.03%

Iron – Balance

Toughness 3.5/10 – Adequate toughness for most cutting tasks but not suitable for large blades subject to a lot of shock and stress, or blades with very thin geometry or fine cutting edges. SLD works best in small to medium sized blades where it can take a sharp edge and hold it all day. It has better toughness than extremely high carbide tool steels like CPM 15V and ZDP-189, lower toughness than most carbon steels, and comparable toughness to many common stainless steels like 440C, 154CM, and N690.

Edge retention 5/10 – Much better edge retention than any carbon steel and better than most stainless steels; lower edge retention than high vanadium stainless and tool steels like CPM S35VN, M390, or CPM M4. SLD's large carbides give it a reputation for taking a toothy edge.

Corrosion resistance 4.5/10 – Moderate resistance to rust, better than most tool steels, slightly less than CPM 3V, falling short of stainless steel corrosion resistance but a huge upgrade over carbon steel. With little maintenance, even a SLD folding knife can stay rust free after years of use and pocket carry.

Recommended heat treatment

- Wrap blade in foil.

- Austenitise – heat to 1,040°C and hold for 10 minutes

- Quench in Aluminium plates

- Temper at 185-200°C for 2 hours, twice, depending on desired hardness

Approximate as-quenched hardness before tempering:

- 1,030°C to 1,070°C followed by cooling to room temperature 64HRC

Recommended working hardness 58-60HRC

A low and long temper is recommended after your normal temper ~100c for 2+ hours to releive any additional stress in the blade and reduce core delamination possibly