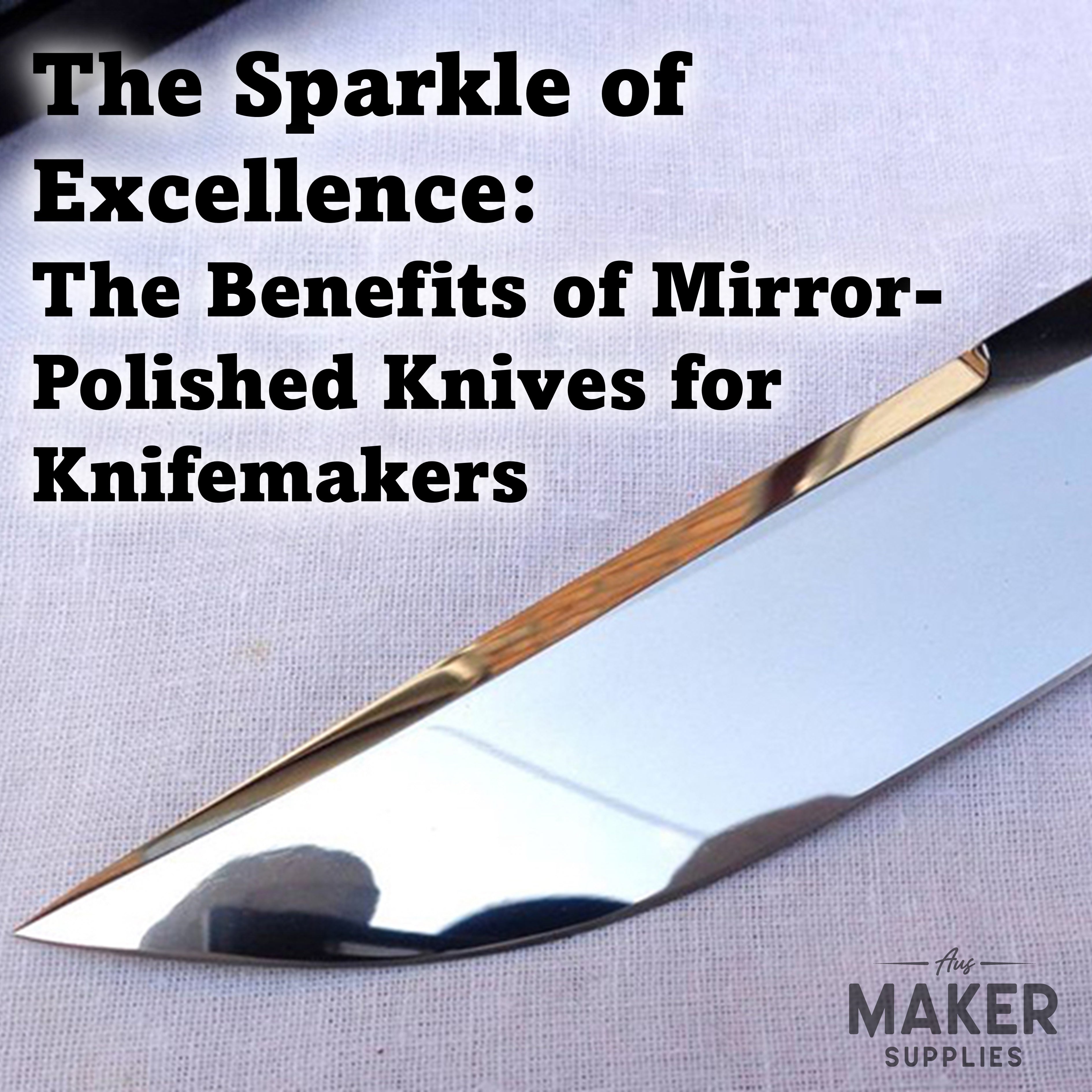

The Sparkle of Excellence: The Benefits of Mirror-Polished Knives for Knifemakers

When it comes to making knives, the finishing touches can make all the difference. Among the various techniques available to enhance the aesthetic appeal of knives, mirror polishing stands out as a timeless and exquisite choice. This article explores the positives and benefits of mirror-polished knives, highlighting why knifemakers should consider incorporating this technique into their repertoire.

1. Enhanced Visual Appeal

The most apparent advantage of mirror-polished knives lies in their stunning visual appeal. When done right the reflective surface of a mirror-polished blade creates a captivating play of light, turning a simple tool into a work of art. Knives with a mirror finish have an irresistible allure that immediately captures the attention of anyone who lays eyes upon them.

2. Exudes Elegance and Sophistication

Mirror-polished knives exude an undeniable sense of elegance and sophistication. The smooth, gleaming surface of the blade symbolizes the meticulous craftsmanship and attention to detail employed by the knifemaker. A mirror-polished knife can enhance the overall aesthetic of a collection, be it in a kitchen, a display case, or on the hip of a discerning chef.

3. Corrosion Resistance

While mirror polishing is primarily regarded as an aesthetic technique, it also offers functional benefits. The mirror finish on a knife's blade provides an additional layer of protection against corrosion and rust. The highly polished surface reduces the scratch pattern on the surface of the steel which minimises space where moisture and dust can accumulate, thus increasing its corrosion resistance and reducing some maintenance requirements.

4. Showcasing Precision and Craftsmanship

Creating a mirror-polished blade requires exceptional skill and attention to detail. By incorporating mirror polishing into their knives, knifemakers can showcase their precision and craftsmanship. It serves as a testament to their dedication and mastery of the art, elevating the value of the knife and establishing a reputation for excellence.

Considering Alternatives

While mirror-polished knives offer numerous advantages, it is important to acknowledge that they might not be suitable for every application or customer preference. Some considerations to keep in mind include:

1. Maintenance

Mirror-polished knives require regular care to maintain their shine. Over time, they may develop small scratches or lose their lustre due to everyday use. Regular polishing and maintenance are necessary to retain the pristine appearance especially on steels that aren’t highly corrosion resistant.

2. Cost

The process of achieving a mirror finish on a knife blade can be time-consuming and labour-intensive, driving up production costs. Knifemakers need to consider whether the added expense aligns with their target market and business goals.

3. Ease of other finishes

Compared to mirror finishes every other finish is a breeze to achieve. Hand sanded satin finishes are a step required to get to mirror, sand blasted is a completely machine finish, acid stone wash just needs a tube of rocks and some ferric. If you're looking for an easy way to finish your knife, mirror finishes are not it.

Conclusion

Mirror-polished knives are a testament to the fusion of artistry and functionality. The allure of their gleaming surfaces captivates enthusiasts, while the functional benefits provide added value for users. Knifemakers seeking to create visually stunning and highly functional blades should consider embracing the technique of mirror polishing. While it may involve additional effort and maintenance, the rewards in terms of aesthetics, corrosion resistance, and the ability to showcase craftsmanship make it a worthwhile endeavour for those striving for excellence in their craft.