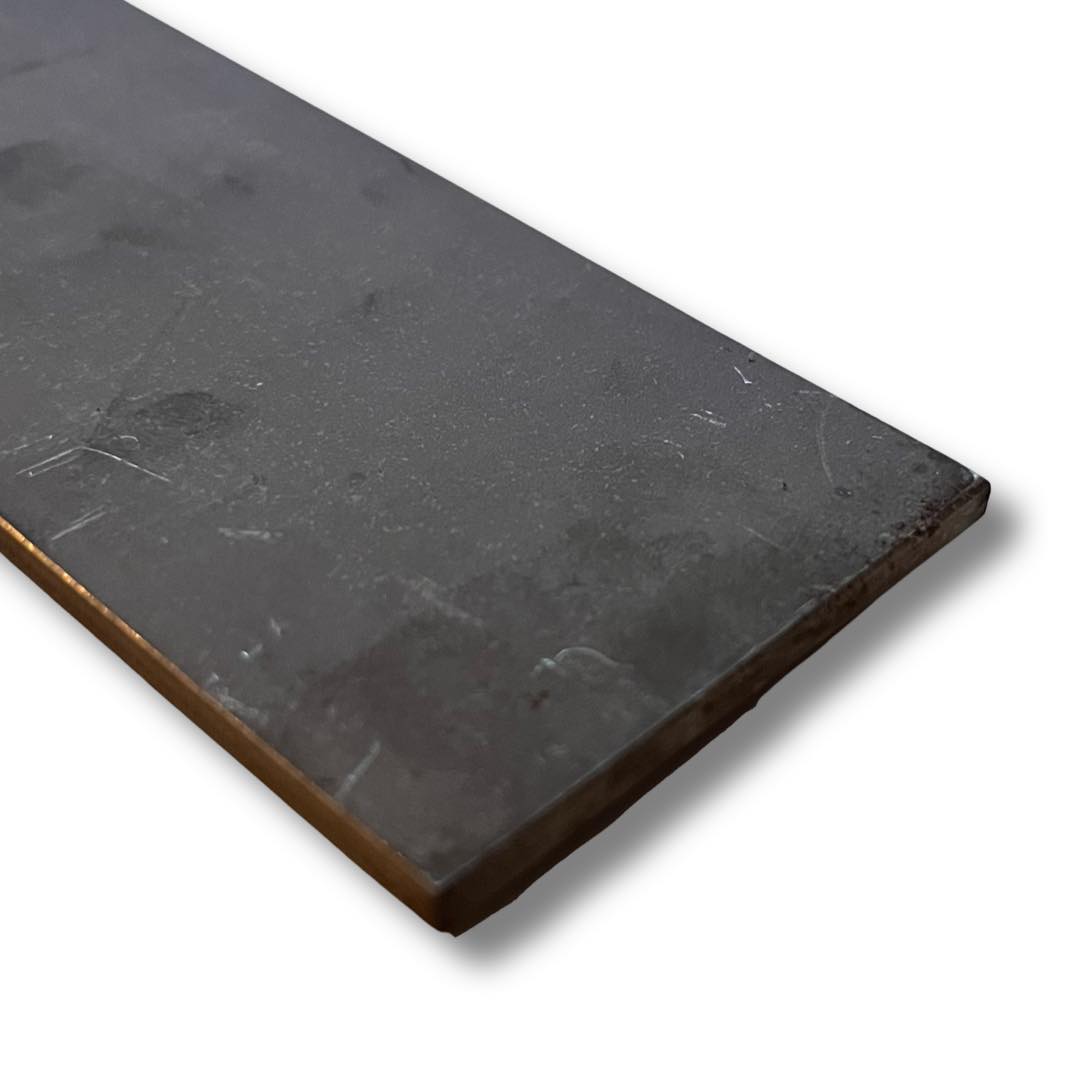

SK5 San Mai Clad 410ss Bars

Premium SK5 tool steel with 410 stainless steel cladding in San Mai construction. These high-carbon steel bars offer exceptional edge retention and durability, making them ideal for knife making and precision tool crafting.

- High-carbon SK5 core for superior hardness

- 410 stainless steel cladding for corrosion resistance

- San Mai laminated construction

- Dimensions: 3mm x 50mm x 500mm

- Perfect for custom blade projects

Chemical Composition (SK5 Core)

-

Carbon: 0.80-0.90%

-

Silicon: 0.10-0.35%

-

Manganese: 0.20-0.50%

-

Phosphorus: ≤0.030%

-

Sulfur: ≤0.020%

-

Iron: Balance

Heat Treatment Instructions

-

Normalize: Heat to 900°C, air cool

-

Harden: Heat to 780-800°C, quench in oil

-

Temper: 150-200°C for 2 hours depending on desired hardness

-

Final hardness: 58-62 HRC when properly heat treated

Experience the perfect balance of hardness and flexibility with these professionally crafted steel bars, designed for serious makers who demand quality materials.