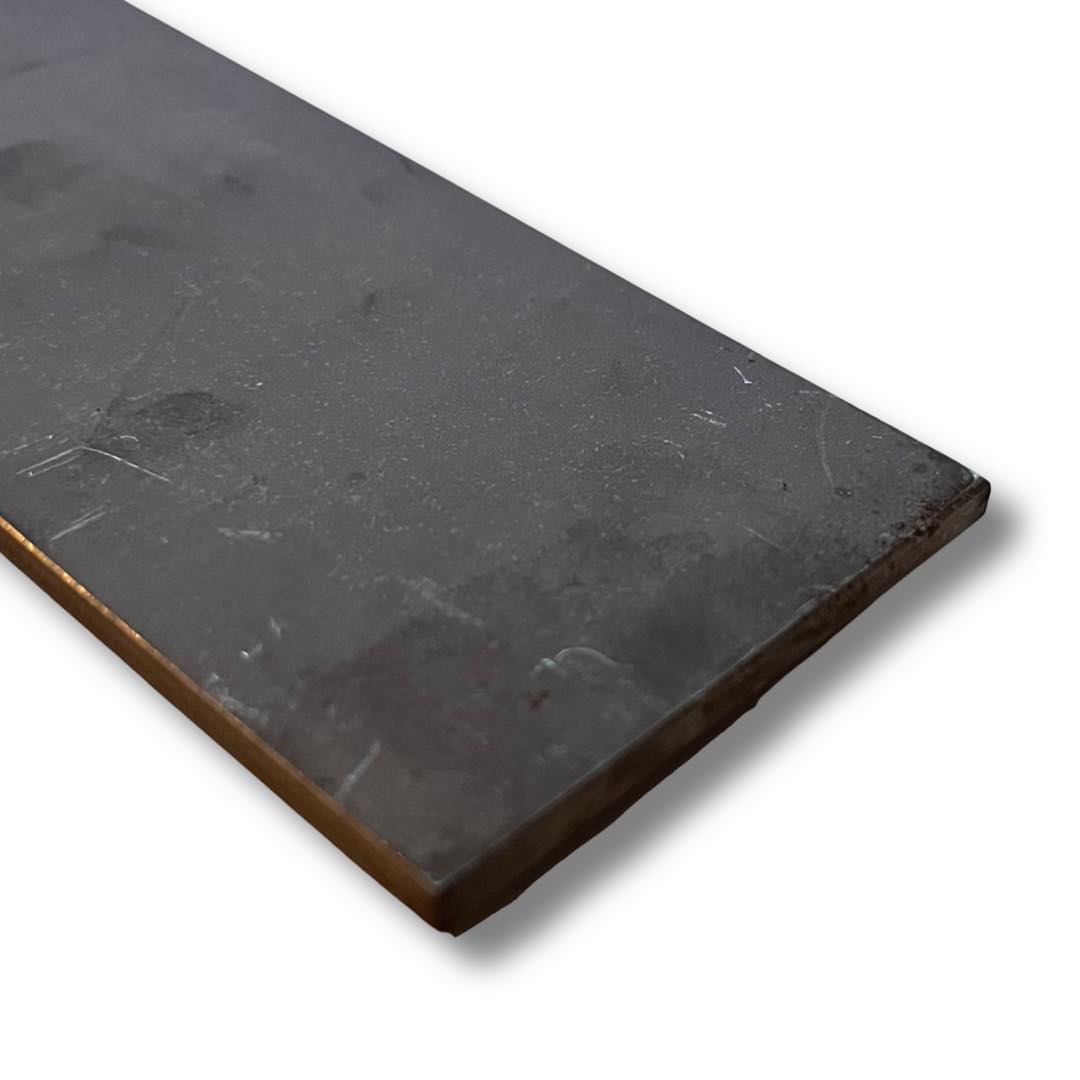

8Cr14Mov Stainless Damascus Clad

8Cr14Mov San Mai with Damascus Stainless Steel Cladding, Made by Sanwa Special Steel company.

This steel is supplied cold rolled and annealed. It has a smooth surface free of decarburisation or pitting and is soft and easily cut, ground, drilled, and filed. Once polished etch in Hydrochloric and ferric acid to bring out the pattern.

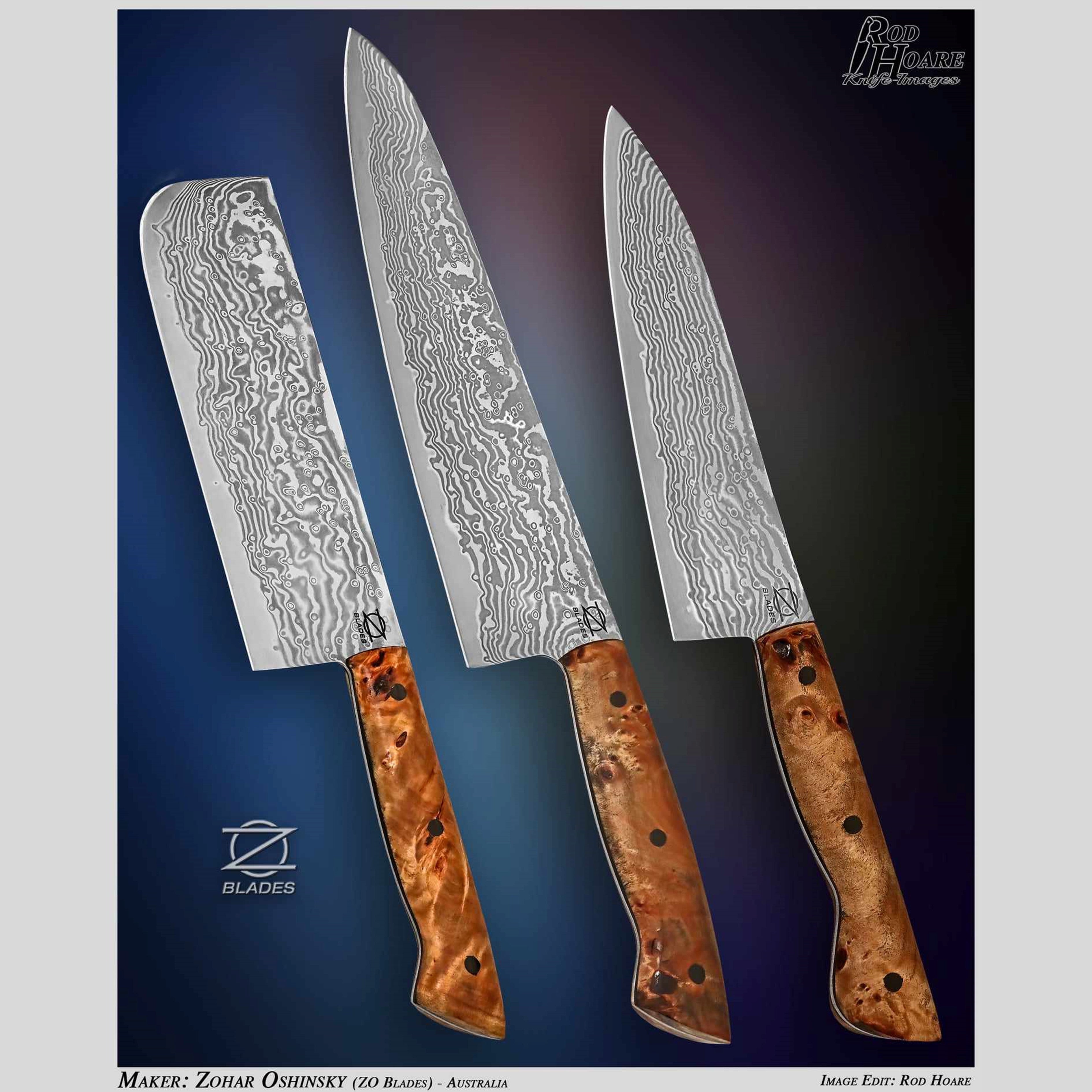

If you dont micro texture (Hammer while cold/hot) to disrupt the pattern you will get straight layers.

8Cr14MoV is a high carbon high chromium martensitic stainless steel. After heat treatment (quenching and tempering), it has high hardness, high wear resistance, and good abrasion resistance and corrosion resistance.

Commonly used in many Spyderco and Benchmade Knives. Similar class of steel to Aus8.

Carbon – 0.75%

Chromium – 14.00%

Molybdenum – 0.25%

Vanadium – 0.15%

Manganese – 0.50%

Silicon – 0.50%

Iron – Balance

Toughness 6/10 – Medium to high toughness, tougher than all other stainless steels and most carbon and tool steels; suitable for a wide range of blade sizes.

Edge retention 5/10 – Better edge retention than almost all carbon steels, lower edge retention than most stainless steels. Easily blunted by abrasive wear but extremely good edge stability resistant to chipping and rolling. Lower abrasive wear resistance also means 8CrMov13 is easier to grind, hand sand, and polish compared to other stainless steels, especially alloys high in vanadium.

Corrosion resistance 7/10 – Adequate resistance to rust, on par with many other common stainless steels like CPM 154 and Nitro-V.

Recommended heat treatment

- Coat blade in an anti scale compound or seal in double crimped 321 or 309 grade stainless steel tool wrap

- Austenitise – heat to 1050°C and hold for 10 minutes

- Quench between aluminium plates, or air quench, or oil quench

- Temper at 150-230°C for 2 hours, twice, depending on desired hardness

Approximate as-quenched hardness before tempering:

- 1050°C followed by cooling to room temperature 60HRC

Recommended working hardness 59-60HRC

NOTE

A low and long temper is recommended after your normal temper ~100c for 2+ hours to releive any additional stress in the blade and reduce core delamination possibly