15N20 - High Carbon Nickel Blade Steel

This steel is manufactured is supplied annealed. It has a smooth surface, making it easy to cut, grind, drill, and file in its annealed state. Thickness may vary slightly from batch to batch.

Made by CSCJ

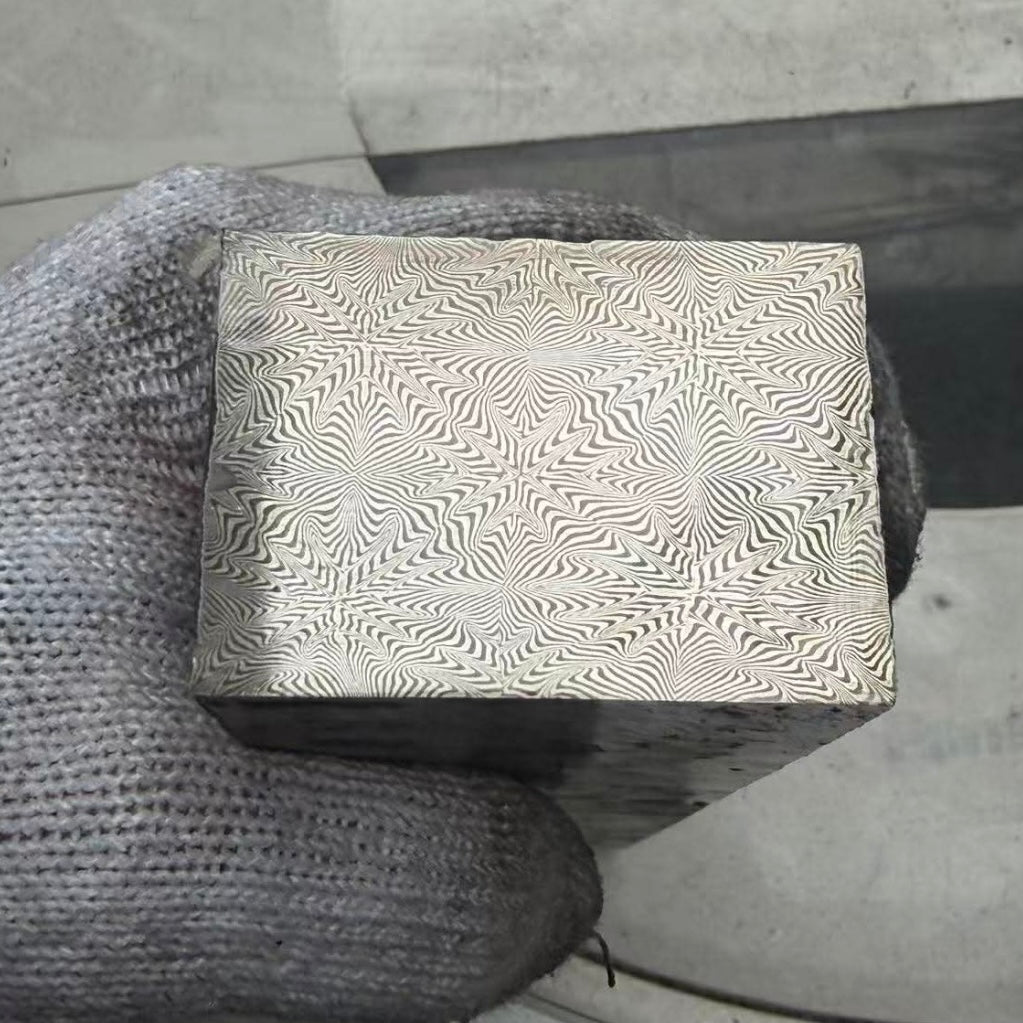

15N20 High Carbon Blade Steel is a high-nickel alloy steel that is frequently paired with 1084 in the creation of pattern-welded or Damascus steel. Its high nickel content gives it excellent toughness and helps produce bright contrast when combined with other carbon steels in forge welding. 15N20 is also an excellent standalone steel, known for its durability, ability to take a sharp edge, and toughness, making it well-suited for large knives, saw blades, and tools requiring a combination of hardness and flexibility.

It is relatively easy to heat treat and is favoured for creating durable, high-performance blades.

Composition

- Carbon – 0.75%

- Nickel – 2.00%

- Manganese – 0.40%

- Silicon – 0.30%

- Chromium – 0.10%

- Iron – Balance

Performance Characteristics

-

Toughness 8/10 – 15N20 is highly regarded for its toughness, making it ideal for larger blades like machetes and axes, as well as knives subjected to heavy use. It offers greater toughness than many other high-carbon steels and is resistant to chipping and cracking under stress.

-

Edge retention 6/10 – While 15N20 offers good edge retention, it does not perform as well in this area as modern, high-alloy steels with vanadium or other hard carbides. However, it holds an edge well in general-use applications and is relatively easy to sharpen, even after prolonged use.

-

Corrosion resistance 3/10 – Though more corrosion-resistant than simple high-carbon steels like 1084 due to its nickel content, 15N20 still requires regular maintenance to prevent rust. It is not stainless, and care should be taken to oil and protect the steel, particularly in humid or wet conditions.

Recommended Heat Treatment

- Heat blade to 820-860°C (non-magnetic stage)

-

Quench immediately in medium-speed oil like canola or parks 50 to achieve optimal hardness

- Temper at 150-200°C for 2 hours, twice, depending on desired hardness

Note: 15N20 is forgiving in heat treatment and can be quenched in oil without the need for advanced setups. When combined with 1084 in Damascus steel, the high nickel content helps to create striking visual contrast after etching, making it a preferred steel in pattern welding.

Approximate As-Quenched Hardness Before Tempering:

- 820-860°C followed by oil quench – 62-64HRC

Recommended Working Hardness

58-62HRC